Product Center

On - site Support and Installation

Stable quality

Stable quality Reasonable price

Reasonable price Quick delivery

Quick delivery

We also offer on - site support services to ensure a smooth installation process. Our professional technical team will assist your construction workers with installation on - site, providing guidance, training, and promptly resolving any potential issues. We work closely with you to ensure that the formwork is installed correctly and efficiently, minimizing potential delays and problems.

Grade | Tungsten Carbide Content | Cobalt Content | Density | |

| YG6 | 94 | 6 | 14.7-15.1 | 89.5 |

| YG8 | 92 | 8 | 14.6-14.9 | 89 |

| YG11 | 89 | 11 | 14.3-14.8 | 88 |

| YG15 | 85 | 15 | 13.9-14.2 | 86.5 |

| YG20 | 80 | 20 | 13.4-13.8 | 83.5 |

| YG20C | 80 | 20 | 13.4-13.8 | 82 |

| YL10.2 | 90 | 10 | 14.4-14.55 | 92.5 |

| YGH20 | 90 | 10 | 14.2-14.5 | 86 |

| YGH25 | 88 | 12 | 14.0-14.3 | 84 |

| YGH30 | 85 | 15 | 13.8-14.2 | 83.5 |

| YGH40 | 82 | 18 | 13.4-13.9 | 83 |

| YGH45 | 80 | 20 | 13.3-13.9 | 82 |

| YGH55 | 74 | 26 | 12.6-13.2 | 81 |

| YGR20 | 90 | 10 | 14.2-14.8 | 85 |

| YGR25 | 87.5 | 12.5 | 14.0-14.3 | 83 |

| YGR30 | 85 | 15 | 13.8-14.3 | 83 |

| YGR40 | 82 | 18 | 13.5-13.9 | 82 |

| YGR45 | 80 | 20 | 13.4-13.9 | 80.5 |

| YGR55 | 75 | 25 | 12.9-13.4 | 79 |

| YGR60 | 70 | 30 | 12.6-13.1 | 78.5 |

-

Wide application range and short construction

Wide application range and short construction

Suitable for walls, floor ceilings,columns, beams, stairs, window sills,bay windows, settlement and otherparts, the aluminum formwork useslighter fixtures and square pipesgreatly reducing the labor intensity ofinstallation workers and improvinginstallation efficiency.

-

Good stability, no need for plastering

Good stability, no need for plastering

The 6061-T6 series aluminum alloyformwork system product is used,and the reinforced overall framehas a bearing capacity of up to60kN/m. After the formwork isremoved, the finish can meet therequirements of plain concrete.

-

Low construction cost and high recycling value

Low construction cost and high recycling value

Normal construction aluminumformwork can be used more than200 times, and all aluminumformwork is made of aluminumalloy material. After the formwork isscrapped, the residual value canreach 20% -30% of the purchase price.

-

Low carbon and environmentallyfriendly

Low carbon and environmentallyfriendly

No need to install plastic sheaths orbrush release agents, and no needto brush sheaths or pull tabs afterdemolding, shortening installationtime; Aluminum formwork systemproducts are all reusable products,with no garbage after constructionand demoulding

-

Project - specific Design

Project - specific Design

Our team of experienced engineers will conduct an in - depth study of your project plans, including architectural blueprints, structural designs, and construction schedules. Based on this in - depth understanding, we will create a customized formwork design tailored to your needs, maximizing construction efficiency, ensuring quality, and controlling costs.

-

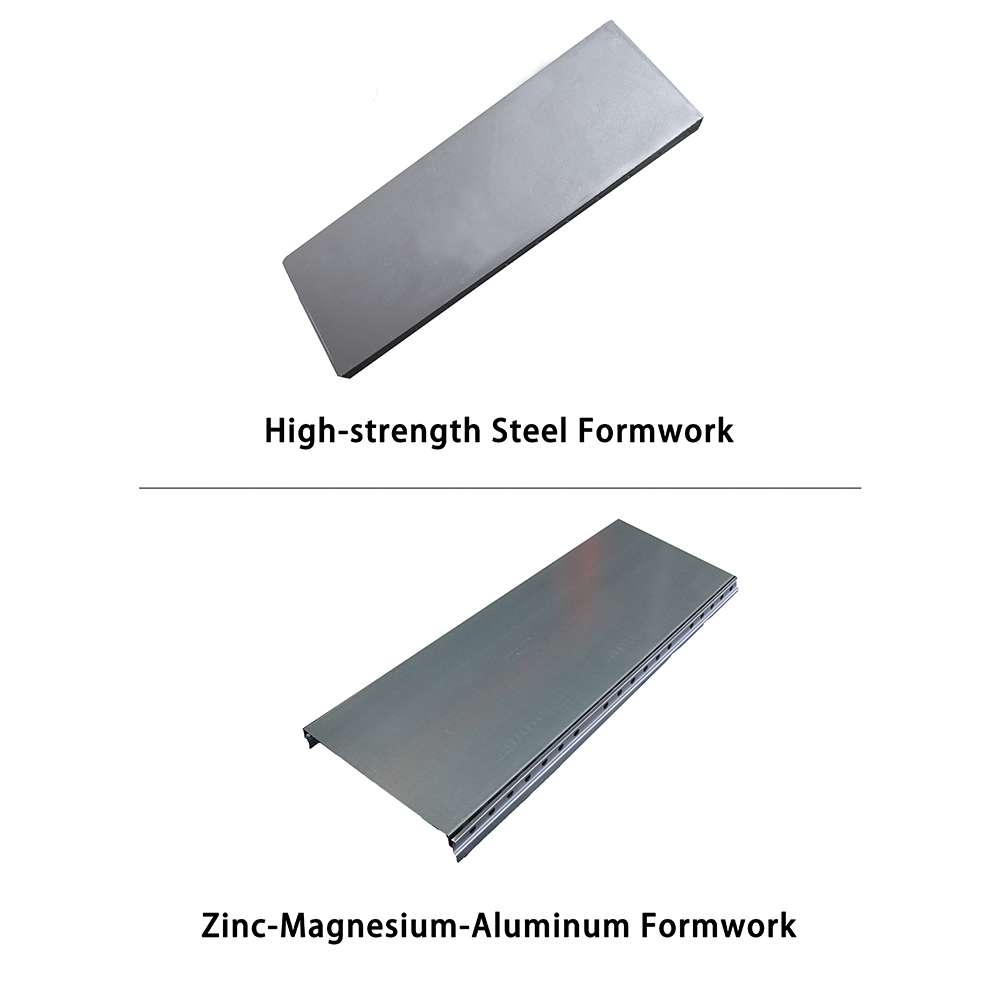

Material Selection

Material Selection

We provide a wide range of high - quality materials for you to choose from. In addition to our signature high - strength alloy, high - quality steel or Zinc-aluminum-magnesium high-strength composite material can also be selected according to project requirements. Our experts will comprehensively consider factors such as durability, weight, corrosion resistance, and budget to provide you with the most suitable material selection advice, ensuring that the formwork solution meets all aspects of the project requirements.

-

Manufacturing Precision

Manufacturing Precision

Once the design plan is determined, our advanced manufacturing plant immediately commences production. Using state - of - the - art machinery and strict quality control processes, each customized formwork component is precisely manufactured. Every formwork is carefully crafted in strict accordance with the design specifications, ensuring seamless splicing and installation at the construction site.

-

On - site Support and Installation

On - site Support and Installation

We also offer on - site support services to ensure a smooth installation process. Our professional technical team will assist your construction workers with installation on - site, providing guidance, training, and promptly resolving any potential issues. We work closely with you to ensure that the formwork is installed correctly and efficiently, minimizing potential delays and problems.

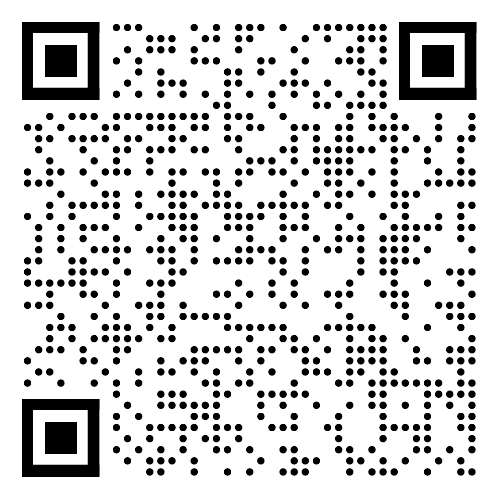

shaanxishoulv@163.com

shaanxishoulv@163.com +86-13785700800

+86-13785700800

EN

EN English

English русский

русский Français

Français Türkçe

Türkçe Español

Español اللغة العربية

اللغة العربية

Add Successfully

Add Successfully

Tel:+86-13785700800

Tel:+86-13785700800 Email:shaanxishoulv@163.com

Email:shaanxishoulv@163.com Adds:Wulang Industrial Park in Chenggu County, Hanzhong City,Shaanxi Province

Adds:Wulang Industrial Park in Chenggu County, Hanzhong City,Shaanxi Province Home

Home WhatsApp

WhatsApp Email

Email