Establishment Time

Patent For Invention

Servive customers

Trade Zone

Shaanxi Shoulv Alu Formwork Technology Co., Ltd. is the first domestic supplier of integrated solutions for aluminum alloy formwork with tension plates and high- strength alloy formwork. Located in the Wulang Industrial Park in Chenggu County, Hanzhong City,Shaanxi Province, the company has a registered capital of 50 million RMB.

Shoulv Alu Formwork Technology Co., Ltd. has a strong research team and an engineering service team with rich on-site construction experience. After years of research and development, the company now offers new products such as stainless steel formwork and high-strength alloy formwork. Especially the high-strength alloy formwork, developed by the team led by Chairman Li Zhongwei, are the first of their kind in China, with multiple patents obtained. The formwork has been applied in projects in provinces such as Shaanxi, Chongqing, Sichuan, Gansu, Ningxia, and Inner Mongolia, receiving high praise and recognition from various construction parties.

Shoulu Formwork & Scaffolding, Integrity to the World.

Using new quality productivity to lead industry development, increase employee benefits, create value for shareholders, and reduce costs for customers. Realize a win-win situation for employees, shareholders, and customers!

Focus on technological innovation, and lead the industry's iteration and upgrading with new materials and new processes.

Create a century old enterprise and become the largest mold frame company in China with the best high-strength alloy template system, the most specialized technology, and the largest scale.

Committed to providing high-quality services to customers and friends

Suitable for walls, floor ceilings,columns, beams, stairs, window sills,bay windows, settlement and otherparts, the aluminum formwork useslighter fixtures and square pipesgreatly reducing the labor intensity ofinstallation workers and improvinginstallation efficiency.

The 6061-T6 series aluminum alloyformwork system product is used,and the reinforced overall framehas a bearing capacity of up to60kN/m. After the formwork isremoved, the finish can meet therequirements of plain concrete.

Normal construction aluminumformwork can be used more than200 times, and all aluminumformwork is made of aluminumalloy material. After the formwork isscrapped, the residual value canreach 20% -30% of the purchase price.

No need to install plastic sheaths orbrush release agents, and no needto brush sheaths or pull tabs afterdemolding, shortening installationtime; Aluminum formwork systemproducts are all reusable products,with no garbage after constructionand demoulding

Industrial Digitization

Intelligent manufacturing greatly enhances efficiency, including independent R&D of the existing formwork renovation production line, formwork automation production line, and robot welding.

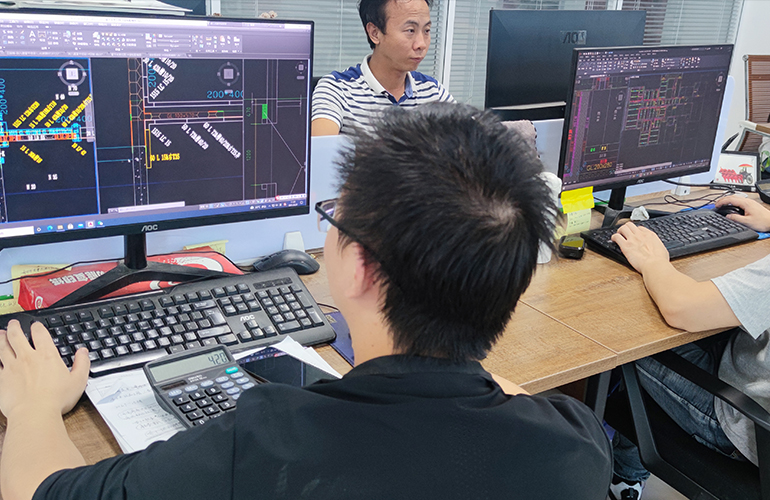

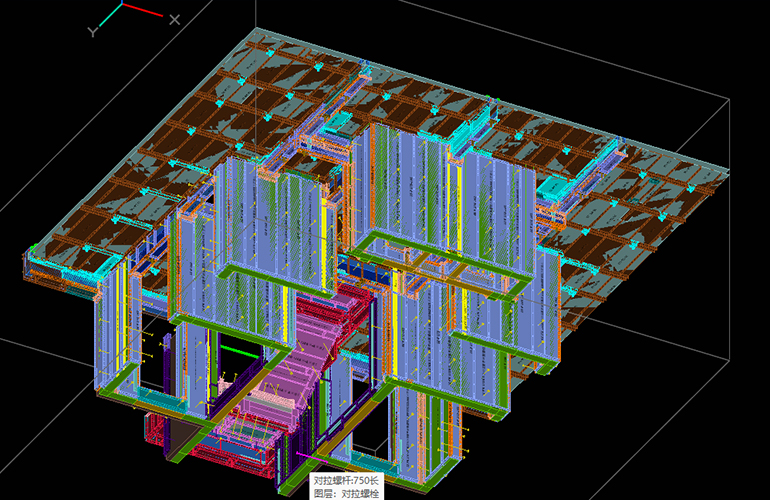

BIM--PKPM Automatic Modulation Software

This software enhances design efficiency and reduces errors, eliminating the need for factory preassembly and enabling faster on-site installation.

The QR code on each panel helps locate materials quickly, enabling workers to assemble the formwork accurately on site.

digital management

Integrates sales, design, supply chain, engineering, and finance into a unified data management platform, enabling comprehensive data analysis and risk monitoring.

Utilizes PDA scanning for real-time warehouse material management based on BIM system outputs.